Understanding Beam Welding Lines A Comprehensive Overview

Beam welding is a critical process in modern manufacturing, particularly within industries such as construction, automotive, and aerospace. A beam welding line is specifically designed for welding structural components, such as beams, girders, and other heavy steel elements. This article delves into the intricacies of beam welding lines, outlining their components, processes, and applications.

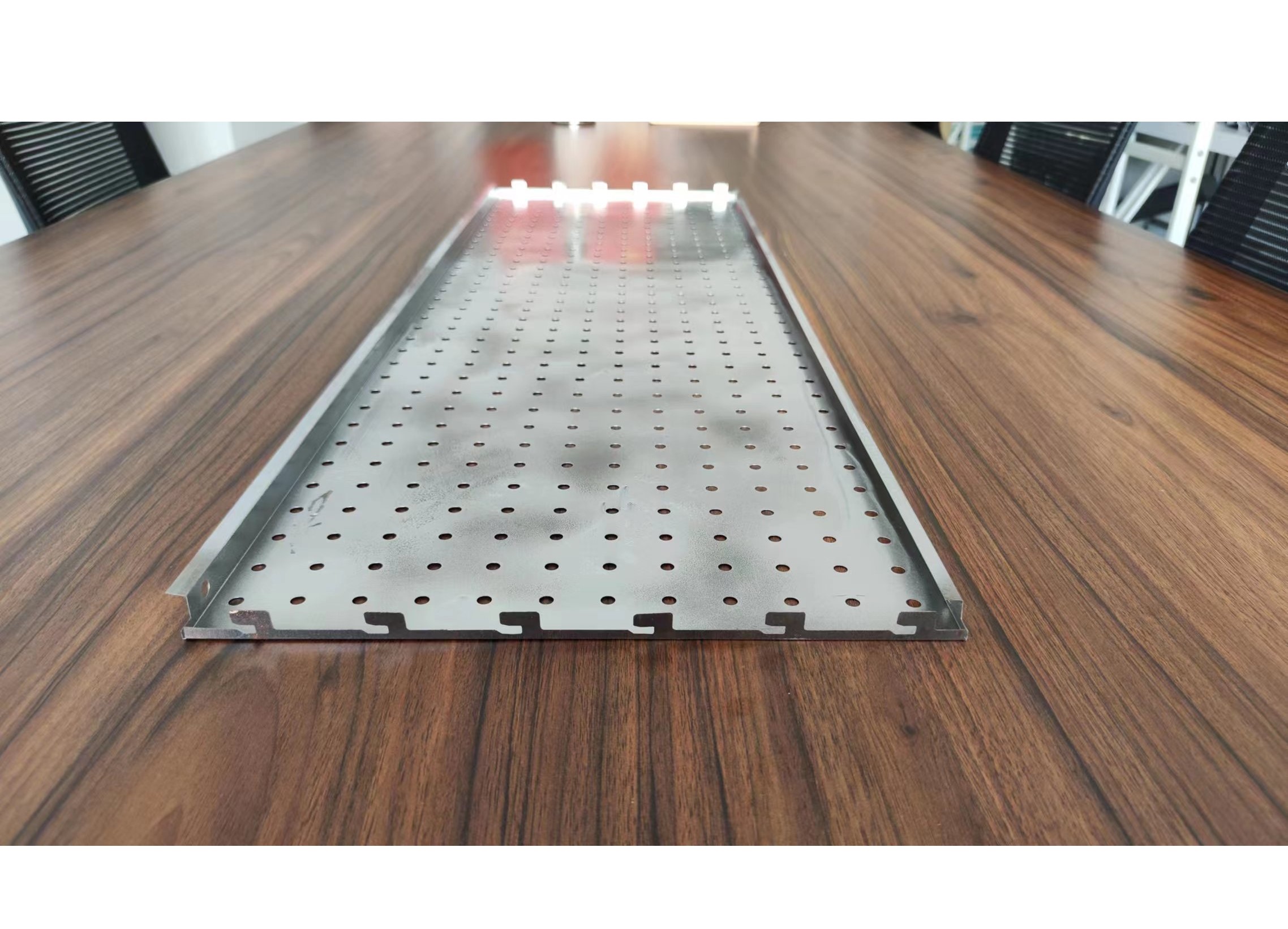

The beam welding line consists of several key components that work in harmony to ensure efficiency and precision. At its core, the line includes automated welding machines that can perform various welding techniques, such as MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and submerged arc welding. These machines are equipped with advanced control systems that allow for real-time monitoring and adjustments, ensuring consistent weld quality.

The setup of a beam welding line typically includes several stages preparation, welding, and finishing

. During the preparation stage, raw materials, usually structural steel, are cut to size and cleaned to remove any contaminants that could affect the weld. This is often done using high-precision cutting tools, such as plasma cutters or laser systems, which ensure the edges are smooth and ready for welding.Once the preparation is complete, the welding stage begins. The components are positioned accurately using jigs and fixtures to maintain alignment during the welding process. Automated welding machines then execute the welding according to pre-set parameters, ensuring uniform heat distribution and penetration. The choice of welding method can influence the properties of the welded material, making it essential to select the right technique based on the project requirements.

After the welding process, the line moves into the finishing stage, where welded beams undergo inspection and testing to ensure they meet necessary quality standards. Techniques such as non-destructive testing (NDT) are commonly employed to detect any internal defects that may compromise the structural integrity of the beams. The final inspection may also include visual assessments and dimensional checks to confirm that the finished product meets specifications.

The applications of beam welding lines are extensive. In construction, beam welding is used to fabricate steel frameworks for buildings and bridges, providing the necessary strength and durability. In the automotive industry, welded beams are integral to vehicle chassis and structural components, contributing to safety and performance. Similarly, in aerospace, beam welding is employed to create lightweight, strong components that can withstand extreme conditions.

Advancements in technology continue to enhance the capabilities of beam welding lines. The integration of robotics and artificial intelligence has led to higher efficiency, precision, and flexibility in production. These innovations enable manufacturers to respond swiftly to market demands and customize products to meet specific client needs.

In summary, beam welding lines are vital components of modern manufacturing processes. With their advanced technology and systematic approach, they ensure the production of high-quality welded structures essential for various industries. As technology continues to evolve, we can expect beam welding lines to become even more efficient and versatile, further enhancing their role in global manufacturing.