Steel Cable Tray Making Roll Forming Machine Revolutionizing Cable Management Solutions

In today’s fast-paced industrial environment, efficient and reliable cable management solutions are essential for effective electrical installations. One of the prominent innovations in this field is the Steel Cable Tray Making Roll Forming Machine. This advanced machinery not only streamlines the production process of cable trays but also enhances the quality and durability of the finished product.

Understanding Cable Trays and Their Importance

Cable trays play a crucial role in the organization and support of electrical cables in commercial and industrial settings. They offer several advantages, including safety, ease of installation, and maintenance. By providing a structured path for cables, cable trays help prevent tangling and damage, thus promoting safer working environments.

Because of their significance, the demand for high-quality cable trays has surged in recent years. Manufacturers are now required to design and produce trays that cater to various applications, including power distribution, telecommunications, and control systems. This is where the Steel Cable Tray Making Roll Forming Machine comes into play.

What is a Roll Forming Machine?

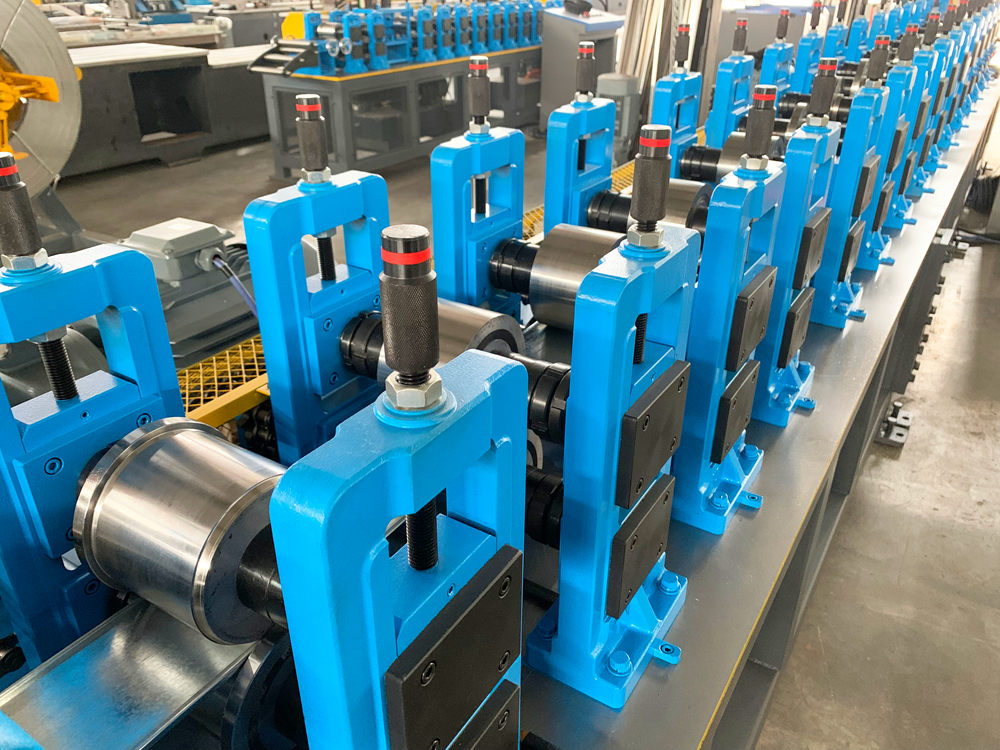

A roll forming machine is a type of fabrication equipment used to shape and bend metal into desired profiles through a series of rollers. In the case of steel cable tray production, the roll forming machine employs a continuous process where steel strips are fed through a sequence of rollers that gradually shape them into a final product. This method is highly efficient and enables high-speed production with minimal waste.

Features and Advantages of Steel Cable Tray Making Roll Forming Machines

1. High Efficiency One of the primary benefits of roll forming machines is their ability to produce large quantities of cable trays in a short period. This efficiency is crucial in meeting the growing demands of various industries.

2. Precision and Consistency Roll forming machines ensure that each cable tray is produced with consistency in dimensions and quality. This precision is vital for installation, as it ensures that trays fit together seamlessly, thereby reducing installation time and labor costs.

3. Versatility Modern roll forming machines are designed to accommodate various steel thicknesses and sizes, making them versatile for different applications. Manufacturers can produce trays with custom shapes and dimensions to meet client specifications.

4. Durability The use of high-quality steel in the construction of cable trays ensures that they can withstand harsh environmental conditions. Roll forming helps to strengthen the material, which enhances the durability and load-bearing capacity of the trays.

5. Cost-effectiveness By optimizing material usage and reducing labor costs, roll forming technology leads to cost savings for manufacturers. This affordability allows businesses to offer competitive pricing without compromising on quality.

The Manufacturing Process

The process of producing steel cable trays with a roll forming machine involves several stages. Initially, sheets of steel are fed into the machine, where they are guided through multiple rollers. Each roller imparts a specific shape or contour to the steel, gradually forming it into a cable tray profile. The final product can then be cut to the desired length and undergo additional processes such as welding, if necessary.

Quality control is an integral part of the manufacturing process. Automated systems monitor dimensions and surface quality to ensure that each piece meets industry standards before leaving the production line.

Conclusion

The Steel Cable Tray Making Roll Forming Machine represents a significant advancement in cable management technology. By offering high efficiency, precision, versatility, and durability, these machines have revolutionized the way cable trays are manufactured. As industries continue to evolve and expand, the need for reliable and efficient cable management solutions will only grow. Investing in advanced roll forming technology could be the key for manufacturers aiming to meet the challenges of the modern industrial landscape. In a world where safety and organization are paramount, the importance of high-quality cable trays cannot be overstated. With the capabilities of roll forming machines, manufacturers are well-equipped to provide the solutions necessary for a safer and more efficient future.