Pipe thread rolling machines have become essential tools in the industrial landscape, revolutionizing the way manufacturers approach threading tasks. As an experienced professional in the engineering and manufacturing sector, I've witnessed firsthand the transformative impact of these machines on production efficiency, product quality, and operational cost-effectiveness.

The sophistication of modern pipe thread rolling machines lies in their ability to produce threads that are both precise and robust. These machines employ a cold forming process that reshapes the material to form threads rather than cutting away material as in traditional threading methods. This not only strengthens the thread but also enhances its fatigue resistance, making it an excellent choice for applications where durability and integrity are of utmost importance.

From an expertise standpoint, the operation of pipe thread rolling machines demands a comprehensive understanding of the mechanics involved. It is essential to consider factors such as material compatibility, thread standards, and the specific application requirements. Engineers and technicians must ensure that the machine settings align with the desired thread characteristics, taking into account the pitch, depth, and angle to achieve optimal results. This level of precision underscores the professional acumen required to maximize the machine's capabilities.

In terms of authoritativeness, the adoption of pipe thread rolling machines by leading industry players speaks volumes about their reliability and efficiency. Renowned manufacturers across the globe rely on these machines to meet stringent quality standards while optimizing production cycles. The credibility of these machines is further bolstered by certifications and compliance with international threading standards, ensuring that products can be used in a wide range of applications, from plumbing to oil and gas industries.

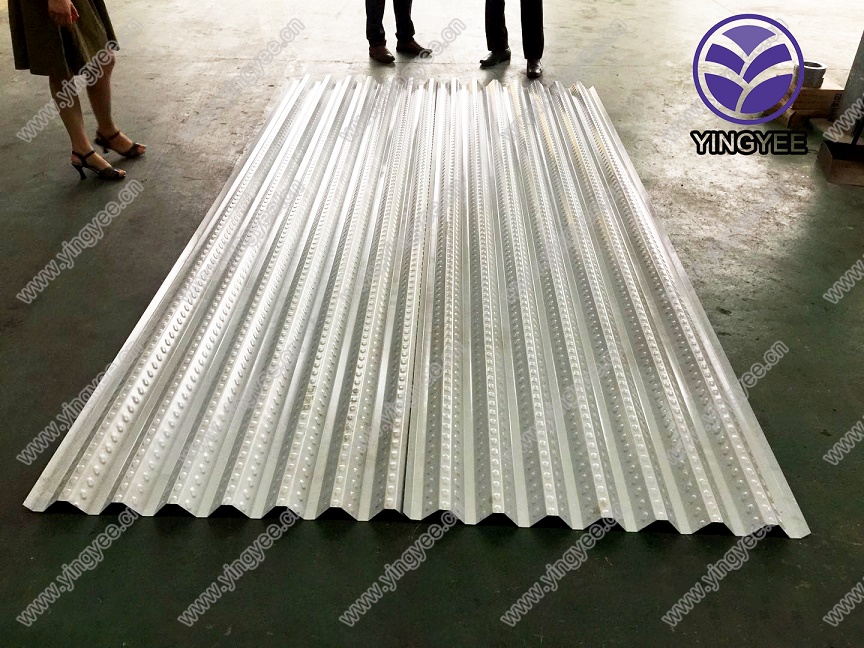

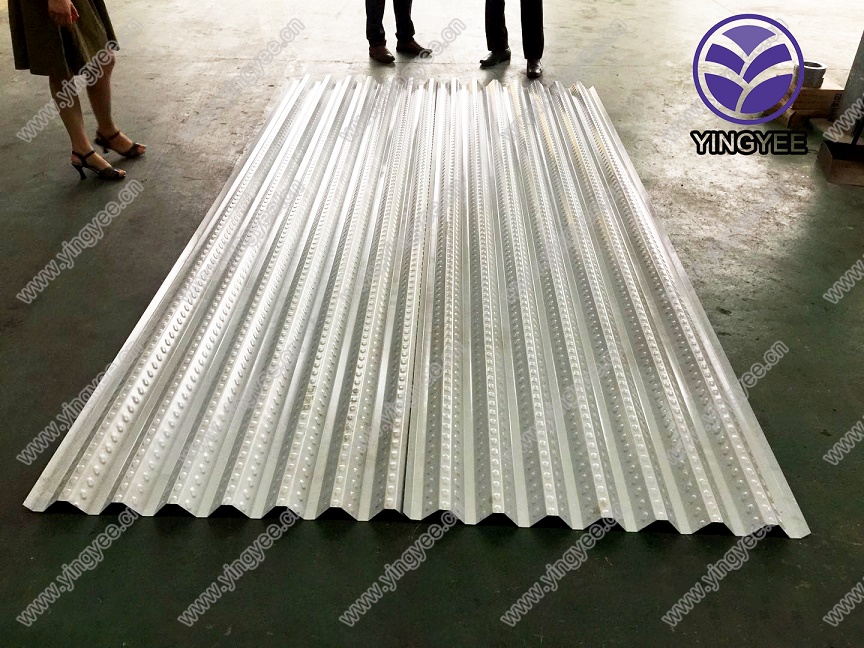

pipe thread rolling machine

Trustworthiness is a critical consideration for industry stakeholders when investing in pipe thread rolling machines. Manufacturers offer comprehensive training programs and technical support to ensure that operators are well-versed in best practices and safety protocols. Furthermore, the integration of advanced features such as digital controls and real-time monitoring enhances operational transparency and machine reliability. This not only reduces the risk of operational errors but also builds confidence in the machine's performance across diverse working conditions.

Product innovation in this space continues to advance rapidly. Recent developments have introduced machines with modular designs that allow for easy upgrades and customization to meet evolving industry needs. These advancements make pipe thread rolling machines an adaptable solution, providing manufacturers the flexibility to scale operations without incurring significant capital expenditure.

In conclusion, pipe thread rolling machines stand as a testament to the blend of innovation and engineering excellence. Their impact on threading operations underscores their critical role in modern manufacturing processes. Through accurate and resilient thread formation, operational efficiency, and adaptability, these machines set a standard for threading technology. For businesses aiming to enhance production quality and reduce operational costs, investing in pipe thread rolling machines is a strategic move, ensuring long-term gains and competitive advantage in the marketplace.