Exploring Metal Roof Roll Formers Innovations and Benefits

In the construction and architectural industry, the choice of roofing material can significantly impact the overall performance, aesthetics, and durability of a building. Among the various options available, metal roofing has gained immense popularity due to its advantages over traditional materials. At the heart of the metal roofing industry lies a crucial piece of equipment known as the metal roof roll former. This article will delve into what metal roof roll formers are, how they work, their benefits, and recent innovations in the field.

What is a Metal Roof Roll Former?

A metal roof roll former is a specialized machine used to manufacture metal roofing panels from flat metal sheets. These machines convert coils of metal into various profiles of roofing panels through a continuous bending process. Metal roof roll formers typically work with materials such as galvanized steel, aluminum, copper, and various alloys, providing flexibility in design and functionality.

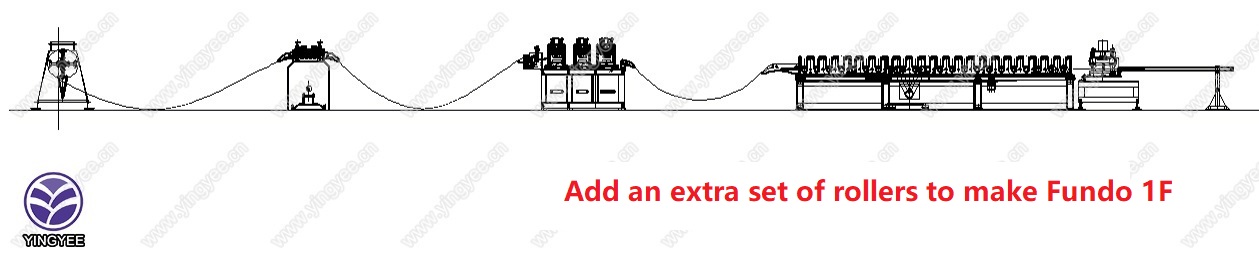

The roll forming process involves a series of rollers that progressively shape the metal sheet into the desired profile. Each set of rollers is designed to bend the sheet slightly more until the final shape is achieved. This highly automated process not only enhances efficiency but also ensures uniformity and precision in the production of metal roofing panels.

How Metal Roof Roll Formers Work

The operation of a metal roof roll former begins with the loading of a coil of metal onto the machine. The coil is then unrolled and fed through a series of rollers. As the metal moves through the machine, each roller applies pressure to create the required bends and angles, ultimately forming a predetermined profile. The process may also include additional elements such as cutting, punching, or crimping, depending on the specific requirements of the roofing panels being produced.

One of the key advantages of metal roof roll formers is their ability to produce long panels that can be cut to the exact length required for a project. This customization minimizes waste and ensures that each panel fits perfectly on the roof, resulting in improved installation efficiency.

Benefits of Using Metal Roof Roll Formers

1. Cost-Effectiveness The efficiency of the roll forming process contributes to lower labor costs and reduced manufacturing time. This economic advantage makes metal roofing more accessible for a variety of construction projects.

2. Durability and Longevity Metal roofing produced by roll formers is often more durable than traditional materials. Metal roofs can withstand extreme weather conditions, resist corrosion, and have a lifespan of 40 years or more, making them a wise investment for property owners.

3. Aesthetic Versatility Metal roof roll formers can create a wide range of profiles and styles, from standing seam to corrugated designs. This versatility allows architects and builders to achieve the desired look without compromising on functionality.

4. Eco-Friendliness Metal roofing materials are often recyclable, making them a more sustainable choice compared to asphalt shingles and other less eco-friendly options. Additionally, many metal roofing products reflect sunlight, contributing to energy efficiency in buildings.

Recent Innovations in Metal Roof Roll Formers

As the demand for metal roofing continues to rise, manufacturers are innovating their roll forming technology to enhance performance and efficiency. Recent advancements include automated systems for real-time monitoring and adjustment, which ensure optimal production quality.

Moreover, newer roll formers are being designed to accommodate a broader range of materials and thicknesses, enhancing the versatility of the production process. Smart technologies, such as IoT integration, are also being introduced to improve predictive maintenance, minimizing downtime and increasing productivity.

Conclusion

In conclusion, metal roof roll formers play a pivotal role in the metal roofing industry, providing significant benefits in terms of cost, durability, and aesthetic versatility. As technology continues to evolve, metal roof roll formers are becoming even more efficient and adaptable, paving the way for innovative roofing solutions. For builders and architects looking to incorporate metal roofing into their projects, understanding the capabilities and advantages of roll formers is essential for making informed decisions and maximizing the potential of metal roofing systems. As we look to the future, it’s clear that the role of metal roof roll formers will only grow in significance within the construction landscape.