Understanding Light Gauge Steel Machines A Key to Modern Construction

Light gauge steel (LGS) has revolutionized the construction industry, offering a durable, lightweight, and cost-effective alternative to traditional building materials. The emergence of light gauge steel machines has further enhanced the efficiency of construction processes, allowing for rapid assembly and superior structural integrity. This article delves into the significance of light gauge steel machines and their impact on modern construction.

Light gauge steel is typically composed of thin sheets of steel that are cold-formed into various structural shapes. These materials are widely used in residential and commercial construction, providing notable advantages such as resistance to fire, pests, and rot, which are common issues with wood framing. The lightweight nature of LGS enables easier transportation and handling on construction sites, reducing labor costs and time delays.

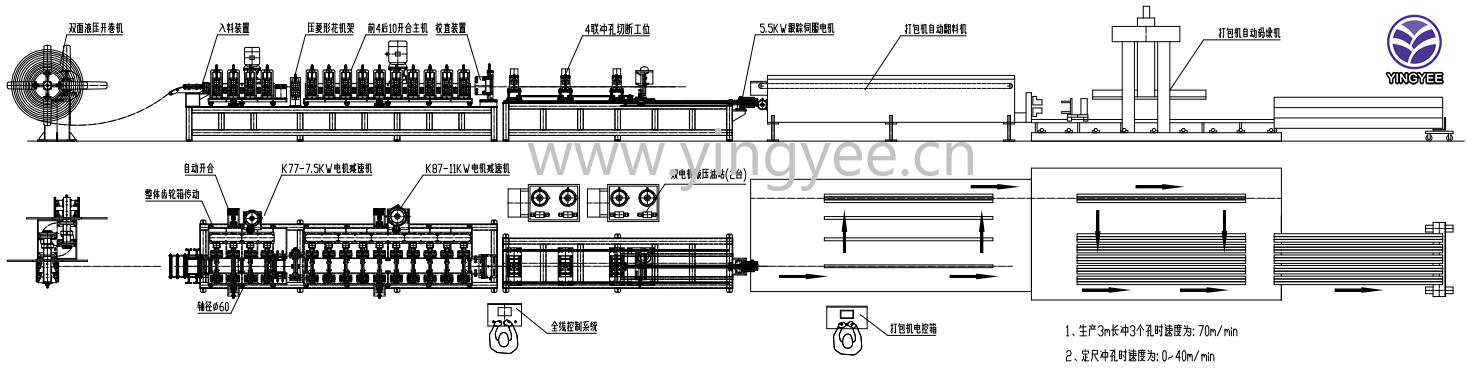

The role of light gauge steel machines in this context cannot be overstated. These specialized machines are designed to cut, shape, and assemble steel components with precision. Automated systems streamline the manufacturing process, ensuring high levels of accuracy that are essential for structural integrity. Furthermore, advanced technology in these machines allows for customization in design, enabling builders to meet specific architectural requirements while adhering to safety standards.

One of the primary benefits of using light gauge steel machines is the speed of construction. Unlike traditional building methods that may require lengthy timelines for framing and assembly, LGS systems can be erected significantly faster. This efficiency is crucial in today's fast-paced construction environment, where project timelines often dictate profitability. The rapid nature of LGS construction also minimizes disruptions and allows for quicker occupancy of buildings.

Sustainability is another important aspect of light gauge steel construction. Steel is recyclable, and utilizing LGS can contribute to eco-friendly building practices. Additionally, as buildings constructed with LGS are often more energy-efficient, they can lead to reduced operational costs and environmental impact over time.

Moreover, the durability and stability of light gauge steel structures make them well-suited for a variety of applications, including residential homes, commercial buildings, and even industrial facilities. The versatility of light gauge steel machines enables builders to create innovative designs, accommodating a wide range of architectural styles and preferences.

In conclusion, light gauge steel machines play a pivotal role in modern construction, driving efficiency and sustainability while enhancing design possibilities. As the industry continues to evolve, the adoption of these machines will likely grow, solidifying light gauge steel's position as a leading choice in construction materials. With their myriad advantages, light gauge steel machines represent the future of building, aligning with the demands of contemporary society for faster, safer, and more sustainable construction solutions.