The Evolution and Benefits of IBR Roof Sheet Forming Machines

In the construction industry, the choice of building materials and methods can significantly influence both the durability and aesthetics of a structure. Among the various roofing options, the IBR (Inverted Box Rib) roof sheets stand out for their unique design and functionality. The IBR roof sheet forming machine has revolutionized the production of these roofing materials, offering numerous advantages for manufacturers and builders alike.

Understanding IBR Roof Sheets

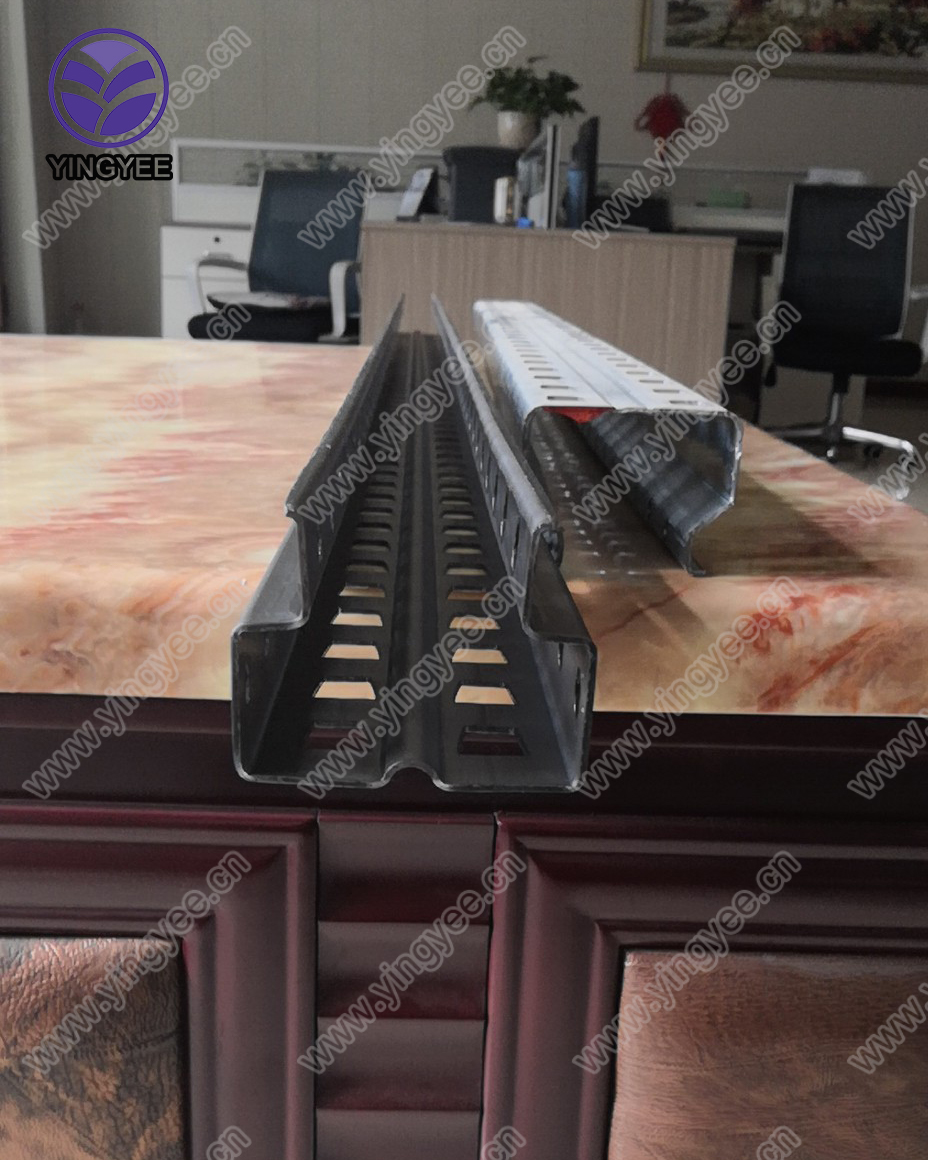

IBR roof sheets are known for their distinctive ribbed profile, which not only enhances their structural strength but also improves their performance in rainwater management. The design promotes better drainage, minimizing the risk of water pooling on the surface, which can lead to leaks and deterioration over time. Typically made from galvanized or color-coated steel, these sheets are lightweight yet resilient, making them an ideal roofing solution for various applications, including residential, commercial, and industrial buildings.

The Role of IBR Roof Sheet Forming Machines

The production of IBR roof sheets requires precision engineering and robust machinery

. The IBR roof sheet forming machine is specifically designed to create these sheets efficiently and consistently. The machine operates by feeding flat metal coils into a series of rollers that gradually shape the material into IBR profiles.Most machines are equipped with adjustable settings, allowing operators to modify the dimensions and rib spacing according to project requirements. Advanced technology also enables some machines to produce varying sheet lengths in a single run, minimizing waste and enhancing productivity.

Key Features and Technologies

Modern IBR roof sheet forming machines incorporate several innovative features

1. Hydraulic Systems Many machines utilize hydraulic systems for better control over the forming process. This results in increased accuracy and reduced wear on the machine components, further extending the machinery’s lifespan.

2. Automated Control Panels With the introduction of programmable logic controllers (PLCs), operators can easily monitor and adjust production parameters. This automation not only boosts efficiency but also reduces the potential for human error.

3. High-Speed Production Advanced IBR roof sheet forming machines are capable of producing sheets at high speeds, meeting the demands of large-scale construction projects without compromising on quality.

4. Versatility These machines can typically handle various gauge sizes and types of metal, allowing manufacturers to diversify their product offerings based on market trends.

Economic and Environmental Benefits

Utilizing IBR roof sheet forming machines presents several economic advantages. Firstly, the speed of production allows manufacturers to increase output and meet tight deadlines, thereby maximizing profits. Furthermore, the durability of IBR roofing reduces maintenance costs over time, as these sheets require less frequent replacement compared to other roofing materials.

Environmental sustainability is also an important consideration. Many IBR roof sheets are manufactured from recyclable materials, and the efficient production processes employed by modern machines minimize energy consumption and waste.

Conclusion

The innovative IBR roof sheet forming machine has fundamentally transformed the roofing industry, offering solutions that are not only cost-effective but also environmentally conscious. As construction practices evolve and demand for sustainable building materials rises, the popularity of IBR roof sheets will likely continue to grow. By investing in advanced forming technology, manufacturers can meet these demands while ensuring that they provide high-quality products that stand the test of time.

As the construction landscape continues to shift toward sustainability and efficiency, the role of IBR roof sheet forming machines will undoubtedly become integral to the future of roofing materials production. With the right machinery, builders can achieve both aesthetic appeal and structural integrity, paving the way for a new era of construction innovation.