The Evolution of the 2% in 1 Making Machine A Revolutionary Tool for Modern Manufacturing

In the fast-paced world of manufacturing, efficiency and adaptability are paramount. The introduction of the 2% in 1 making machine represents a significant leap forward in manufacturing technology, combining two essential production processes into one streamlined piece of equipment. This innovation not only optimizes workflow but also reduces operational costs and minimizes waste, making it a game-changer for industries across the globe.

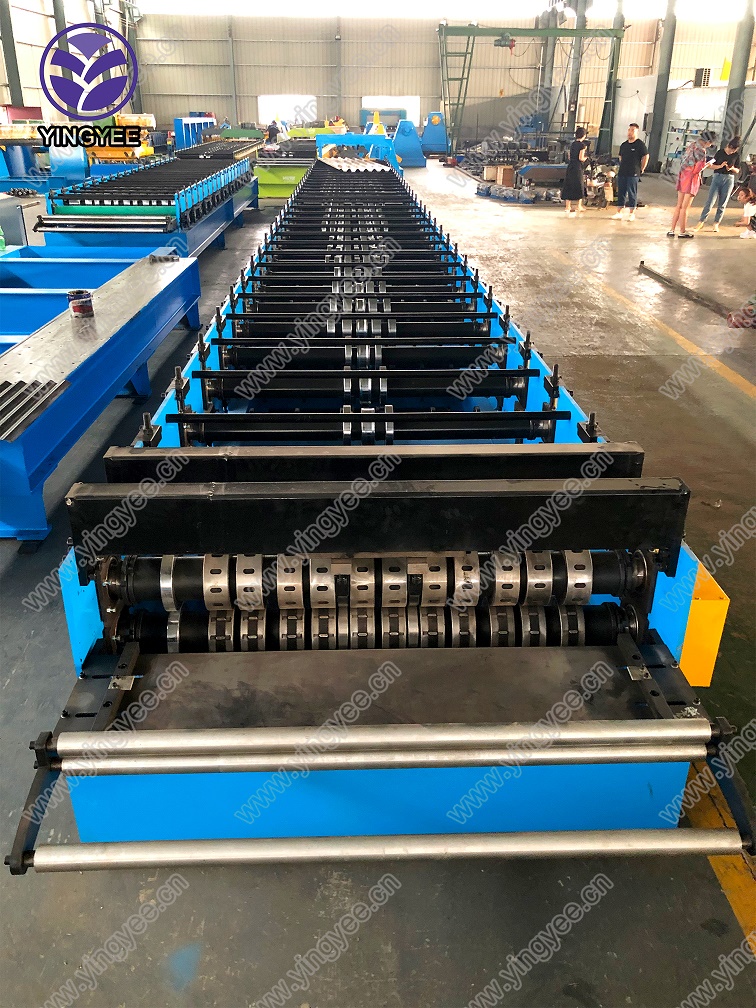

The core concept behind the 2% in 1 making machine is its multifunctionality. Traditionally, manufacturers relied on separate machines for different production stages, which often led to inefficiencies and prolonged production times. By integrating two processes into one machine, manufacturers can achieve quicker turnaround times and a higher output, which is critical in today’s competitive market. The machine essentially takes two functions that would normally require distinct setups and executes them in a cohesive manner, saving time and resources.

How the 2% in 1 Machine Works

The functionality of the 2% in 1 making machine can vary based on its intended application. For instance, it might be used in the textile industry for both weaving and cutting fabrics, or in the food industry for mixing and packaging products. The machine operates on a sophisticated control system that allows operators to adjust settings quickly, facilitating seamless transitions between functions. This level of versatility enables manufacturers to respond to market demands more rapidly, adapting production lines to different products without the need for extensive retooling.

Moreover, the machine is designed with automation in mind. Many models come equipped with advanced sensors and programming capabilities that enhance precision and reduce human error. This not only improves the quality of the output but also further reduces the likelihood of material waste, contributing to more sustainable manufacturing practices.

Advantages of the 2% in 1 Making Machine

1. Cost Efficiency By reducing the number of machines required for production, companies can significantly lower their capital investment costs. Additionally, fewer machines mean lower maintenance costs and reduced energy consumption.

2. Space Optimization In manufacturing environments where space is often at a premium, a compact and multifunctional machine can free up valuable floor space. This can be particularly beneficial for small to medium-sized enterprises looking to maximize their operational footprint without compromising production capacity.

3. Increased Productivity The integration of processes tends to streamline production workflows. Workers can operate the machine with a focus on quality control rather than managing multiple machines, ultimately leading to increased productivity levels.

4. Flexibility and Customization The ability to quickly switch between functions allows manufacturers to offer a wider range of products without the need for significant reconfiguration. This flexibility is especially advantageous in industries with rapidly changing consumer preferences.

Challenges and Considerations

While the benefits of the 2% in 1 making machine are substantial, there are challenges that manufacturers must consider before adoption. One key concern is the initial investment cost and the training required for staff to effectively operate and maintain the new technology. Additionally, the complexity of integrated systems can lead to potential downtime if technical issues arise, which necessitates a robust support system and maintenance regimen.

Another consideration is the need for ongoing innovation. The manufacturing sector is constantly evolving, and staying ahead of technological advancements is crucial for maintaining a competitive edge. Companies must keep an eye on industry trends and be prepared to upgrade their equipment as needed.

Conclusion

The 2% in 1 making machine is more than just a technological innovation; it embodies the future of efficient manufacturing. By combining essential processes into one machine, it offers significant advantages in terms of cost, space, productivity, and flexibility. As industries continue to embrace advancements in technology, the 2% in 1 making machine will likely play a pivotal role in shaping the landscape of modern manufacturing. Embracing such innovations not only enhances operational efficiency but also promotes a sustainable future for manufacturing practices worldwide.