The Hydraulic Guillotine Machine Revolutionizing Cutting Processes

In the modern manufacturing landscape, precision and efficiency are paramount. One machine that exemplifies these attributes is the hydraulic guillotine, which has become a staple in metalworking and sheet processing industries. This robust piece of equipment is designed to provide accurate and clean cuts, making it an essential tool for businesses that require high-quality metalwork.

Understanding the Hydraulic Guillotine

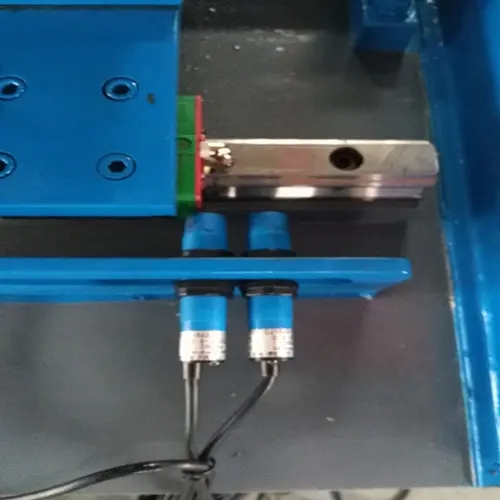

The hydraulic guillotine operates using hydraulic pressure to drive the cutting blade against the material, typically sheet metal. This mechanism not only ensures a powerful cutting force but also allows for precise control over the cutting angle and depth. The design of the guillotine incorporates a fixed blade and a movable blade that descends to make the cut, which is ideal for straight cuts on various materials, including aluminum, steel, and other alloys.

Key Features

One of the standout features of the hydraulic guillotine is its ability to cut thick materials with ease. Unlike traditional mechanical shears, which may struggle with thicker or denser materials, hydraulic machines can handle heavier workloads due to the advantages of hydraulic power. This makes them particularly valuable in industries such as construction, automotive, and aerospace, where cutting through robust materials is often required.

Furthermore, hydraulic guillotines come equipped with digital control systems and programmable settings. Operators can quickly input desired measurements and automatically adjust the machine's parameters for different cutting jobs. This not only enhances precision but also significantly reduces the time spent on setup and calibration, leading to increased productivity on the shop floor.

Benefits of Using Hydraulic Guillotines

The benefits of integrating a hydraulic guillotine into a manufacturing process are numerous. The primary advantage is the quality of the cut; the machine produces smooth, burr-free edges that require little to no post-processing. This high-quality outcome is critical for fabrications that demand a premium finish, thus saving time and resources in secondary operations.

Additionally, the hydraulic guillotine is known for its durability and long lifespan. Constructed from robust materials and featuring efficient engineering, these machines are built to withstand the rigors of daily use. Regular maintenance can further extend their lifespan, making them a worthwhile investment for businesses focused on longevity and performance.

Safety is another critical consideration in metal processing. Hydraulic guillotines are often equipped with safety features such as emergency stops, protective guards, and advanced control systems that help prevent accidents. Operators can execute cuts with confidence, knowing that the machine is designed with their safety in mind.

Conclusion

The hydraulic guillotine machine stands as a testament to the advancements in industrial machining technologies. With its ability to deliver precise, efficient, and high-quality cuts, it has transformed the way professionals approach metal processing. As industries continue to evolve and demand higher standards of production, the hydraulic guillotine will undoubtedly remain a key player in ensuring that precision cutting is both accessible and efficient. Whether for small workshops or large-scale manufacturing setups, investing in a hydraulic guillotine represents a commitment to quality, safety, and operational excellence. With these machines at the forefront of metalworking technology, the future looks bright for manufacturers aiming to enhance their cutting capabilities.