The Advantages of Heavy Duty Storage Rack Roll Forming Machines

In the modern warehouse and manufacturing environment, efficient and organized storage solutions are crucial for maximizing productivity. Among the various storage options, heavy duty storage racks stand out due to their capacity to hold large quantities of materials while optimizing space. The production of these racks relies significantly on advanced roll forming machines, specifically designed for heavy duty storage solutions. This article explores the key features and advantages of heavy duty storage rack roll forming machines.

Understanding Roll Forming Technology

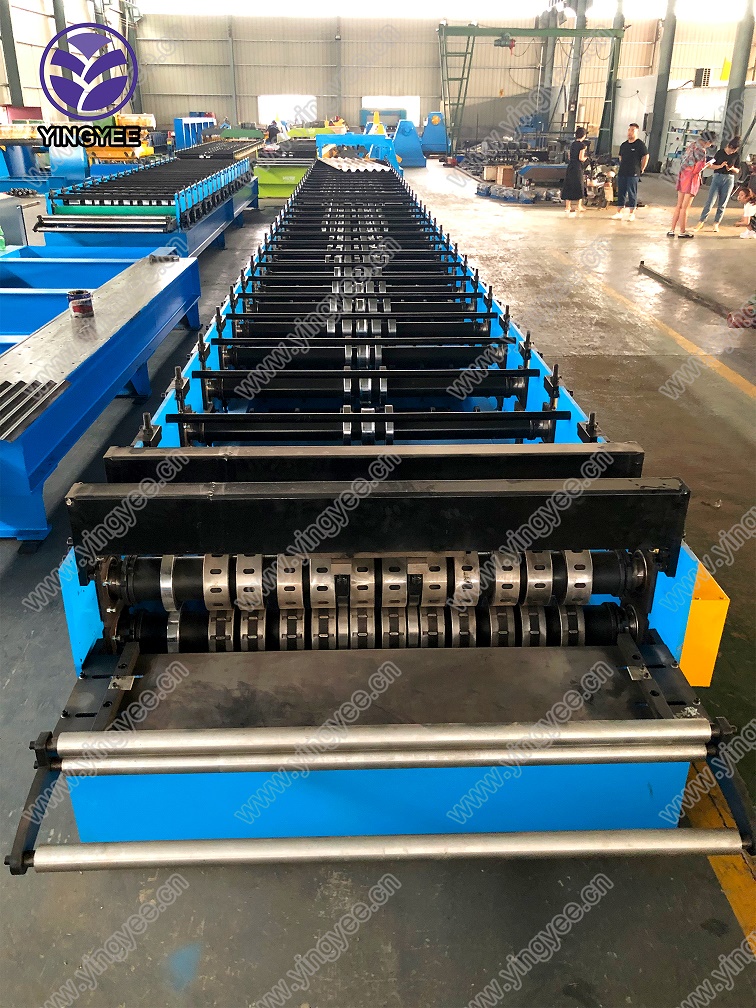

Roll forming is a continuous bending operation in which a long strip of metal is gradually shaped into the desired cross-section. This method is particularly advantageous for producing items that require uniformity and precision, such as heavy duty storage racks. The roll forming machine uses a series of rollers to bend and shape metal sheets, often made from high-strength materials like steel or aluminum, into the desired profiles. Customization options allow manufacturers to create racks that meet specific storage needs and industry standards.

Key Features of Heavy Duty Storage Rack Roll Forming Machines

Heavy duty storage rack roll forming machines are designed with various features that enhance their efficiency and output quality

1. High Production Capacity These machines can handle large volumes of material, producing up to several tons of racks per day. This high production rate is essential for meeting the demands of large-scale warehouses and distribution centers.

2. Precision and Consistency Advanced technology ensures that each piece produced is identical, which is critical in applications where uniformity is necessary for safety and functionality.

3. Durability Roll forming machines are built to withstand the stress of processing tough materials. They are engineered for longevity, reducing downtime and maintenance costs.

4. Customizable Design The flexibility of roll forming allows manufacturers to produce a wide range of rack designs. This includes adjustable shelves, varied dimensions, and additional features like safety bars, all tailored to the specific requirements of clients.

5. Automated Systems Many modern roll forming machines incorporate automation technologies, reducing labor costs and increasing efficiency. Automated feeding, cutting, and stacking mechanisms help streamline the production process.

Advantages of Using Heavy Duty Storage Rack Roll Forming Machines

The benefits of utilizing heavy duty storage rack roll forming machines extend to both manufacturers and end-users

1. Reduced Production Costs By optimizing the manufacturing process, roll forming machines help in reducing waste and minimizing material costs. The efficient use of raw materials translates into significant savings for manufacturers.

2. Quick Turnaround Time The high-speed production capability allows for rapid delivery of racks, enabling businesses to respond promptly to changing market conditions or inventory needs.

3. Enhanced Safety Heavy duty storage racks manufactured with precise measurements reduce the risk of accidents in warehouses. These racks are designed to hold heavy loads safely, providing peace of mind for users.

4. Sustainability The roll forming process generates less waste compared to other manufacturing techniques. Additionally, many manufacturers are adopting eco-friendly materials and practices, contributing to environmental sustainability.

5. Custom Solutions Companies can work closely with manufacturers to design racks that fit their unique storage challenges. This level of customization ensures optimal use of space and resources.

Conclusion

As the demand for efficient storage solutions continues to rise, heavy duty storage rack roll forming machines will play a pivotal role in the industry. Their ability to deliver high-quality, durable, and customizable racks makes them indispensable for manufacturers looking to meet the needs of modern warehouses. By investing in this technology, companies can enhance their production capabilities, reduce costs, and ultimately, improve the efficiency of their operations. The future of storage solutions hinges on the advancements and capabilities offered by roll forming technology, making it a critical component in the evolving landscape of logistics and warehousing.