The Ceiling Panel Rolling Machine Revolutionizing Construction and Design

In recent years, the construction industry has seen remarkable advancements in technology, which have significantly enhanced efficiency and productivity. One of the groundbreaking innovations in this domain is the ceiling panel rolling machine. This sophisticated equipment is designed to streamline the production of ceiling panels, offering a myriad of benefits for manufacturers and architects alike.

Understanding the Ceiling Panel Rolling Machine

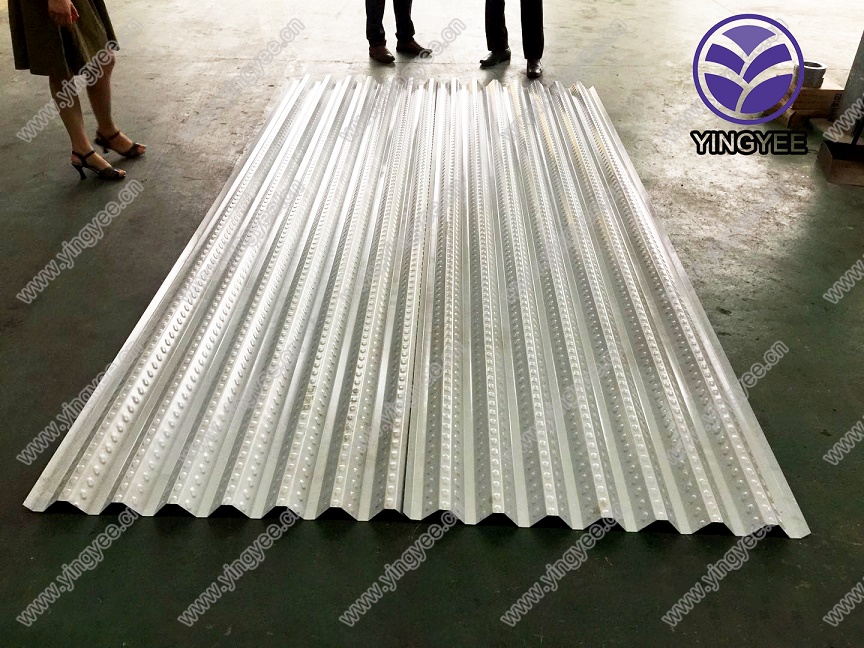

A ceiling panel rolling machine is an industrial device that automates the process of creating ceiling panels from raw materials. The machine works by converting flat sheets of metal or other materials into shaped panels that can be used in commercial and residential construction. This equipment typically features various components, including rollers, cutters, and forming sections that collaboratively shape the material into the desired form.

The primary function of the ceiling panel rolling machine is to ensure precision and uniformity in the production of ceiling panels. With its capability to quickly and efficiently produce panels, it saves time and reduces waste, making it an invaluable addition to any construction facility.

Benefits of Using Ceiling Panel Rolling Machines

1. Increased Efficiency One of the most significant advantages of using a ceiling panel rolling machine is the increased production efficiency. Traditional methods of manufacturing ceiling panels can be labor-intensive and time-consuming. In contrast, a rolling machine can produce panels at a much faster rate, allowing manufacturers to meet high demand without compromising quality.

2. Cost Savings By automating the production process, ceiling panel rolling machines can drastically reduce labor costs. Moreover, the precision of these machines minimizes material waste, making the entire operation more economical. Lower production costs translate to more competitive pricing for end products, benefiting both manufacturers and consumers.

3. Versatility Modern ceiling panel rolling machines are designed to handle various materials and panel designs. From simple flat panels to more complex patterned variations, these machines can cater to diverse architectural styles. This versatility allows manufacturers to expand their product offerings and meet varying customer demands.

4. Consistent Quality The automated nature of ceiling panel rolling machines ensures that each panel produced meets high-quality standards. The precision engineering behind these machines prevents defects and ensures uniformity in size and shape. Consistent quality reduces the need for reworking panels, saving time and resources.

5. Eco-Friendly Production With growing emphasis on sustainability in construction, ceiling panel rolling machines help reduce the environmental impact of production. By minimizing waste and improving efficiency, they contribute to eco-friendly practices in the building industry. Additionally, many of these machines are capable of working with recycled materials, further promoting sustainable construction practices.

The Future of Ceiling Panel Manufacturing

As construction trends evolve, so does the technology behind ceiling panel production. The integration of IoT (Internet of Things) and AI (Artificial Intelligence) into ceiling panel rolling machines is likely to enhance their capabilities even further. Future machines may incorporate smart features for monitoring production in real-time, predictive maintenance to prevent downtime, and improved user interfaces for better control and customization.

Furthermore, with a growing focus on green building practices, manufacturers are exploring options for using more sustainable materials and processes in ceiling panel production. This evolution not only ensures compliance with environmental standards but also appeals to environmentally conscious consumers.

Conclusion

The ceiling panel rolling machine stands as a testament to the innovative strides made in the construction industry. By enhancing efficiency, reducing costs, and providing consistent quality, this equipment plays a pivotal role in modern ceiling panel manufacturing. As technology continues to advance, the future looks promising for ceiling panel production, paving the way for more sustainable and efficient practices in the construction sector. Manufacturers and architects alike should embrace this technology to stay competitive in an ever-evolving market.