Understanding U-Shape Frame Forming Machines An Essential Tool in the Manufacturing Industry

In the realm of modern manufacturing, efficiency and precision are paramount. Among the many tools that help achieve these objectives, the U-shape frame forming machine stands out as a vital piece of equipment. This machine, designed specifically for the fabrication of U-shaped frames, plays an essential role in various industries, including construction, automotive, and furniture manufacturing.

What is a U-Shape Frame Forming Machine?

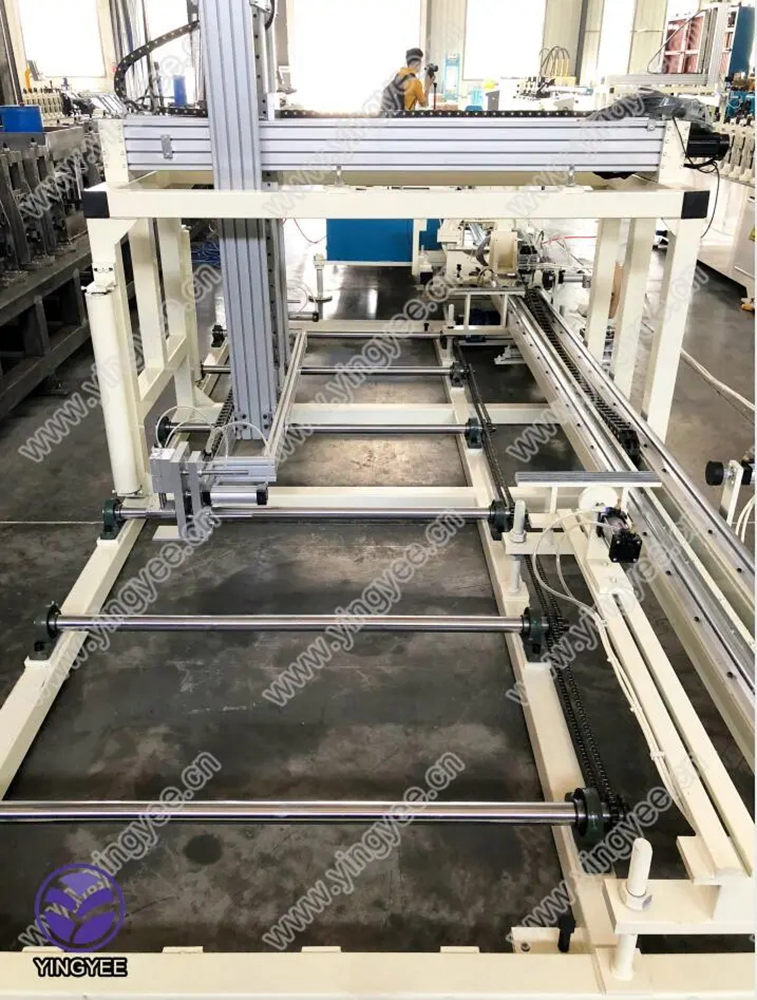

A U-shape frame forming machine is a specialized tool that processes raw materials, typically metal sheets, into U-shaped frames required for various applications. The machine hydraulically bends, cuts, and modifies metals to create structures that can support weight and withstand external forces. These frames are crucial in constructing everything from vehicle chassis to industrial scaffolding.

The Process of U-Shape Frame Forming

The process begins with feeding flat metal sheets into the machine. Equipped with advanced technology and precise sensors, the U-shape frame forming machine utilizes rollers, rollers, and bending tools to gradually shape the metal into the desired U-form. The operation often involves multiple stages, including cutting the material to the right length, heating it to improve malleability, and then deforming it into its final shape.

One of the essential features of these machines is their ability to maintain consistent quality and dimensions. Modern U-shape frame forming machines are often equipped with computer numerical control (CNC) systems, which allow for precise adjustments and repeatability. This ensures that each frame produced is uniform and meets the strict specifications required for structural integrity.

Applications of U-Shape Frames

U-shaped frames have a broad range of applications. In the construction industry, they are indispensable for creating durable frameworks for buildings, bridges, and other structures. In the automotive sector, U-shaped frames are utilized in vehicle manufacturing, supporting essential components and enhancing safety features. Additionally, these frames are found in furniture design, providing sturdy bases for tables, chairs, and shelves.

Benefits of Using U-Shape Frame Forming Machines

The advantages of U-shape frame forming machines extend beyond mere production efficiency. First and foremost, these machines significantly reduce manpower requirements. By automating the bending and shaping processes, manufacturers can allocate human resources to other critical areas of production, thereby enhancing operational workflow.

Moreover, U-shape frame forming machines contribute to reduced material waste. Sophisticated cutting and shaping techniques allow for optimal use of raw materials, thus lowering production costs and minimizing environmental impact.

Future Trends in U-Shape Frame Forming Technology

As the manufacturing sector continues to evolve, so too does the technology behind U-shape frame forming machines. Innovations such as advanced automation, improved energy efficiency, and enhanced software integration are being integrated into these machines. Moreover, the push towards sustainable manufacturing practices is leading to the development of machines that use eco-friendly materials and processes.

In conclusion, the U-shape frame forming machine is an indispensable tool in the modern manufacturing landscape. Its ability to produce high-quality, precise, and durable frames plays a crucial role in the construction, automotive, and furniture industries. As technology continues to advance, these machines will undoubtedly become even more efficient, paving the way for a more productive and sustainable future in manufacturing.