Light Gauge Steel Framing Machine A Revolution in Construction

In recent years, the construction industry has witnessed significant advancements in technology, particularly with the introduction of light gauge steel framing machines. These machines have revolutionized the way buildings are constructed, providing a wealth of benefits over traditional framing methods.

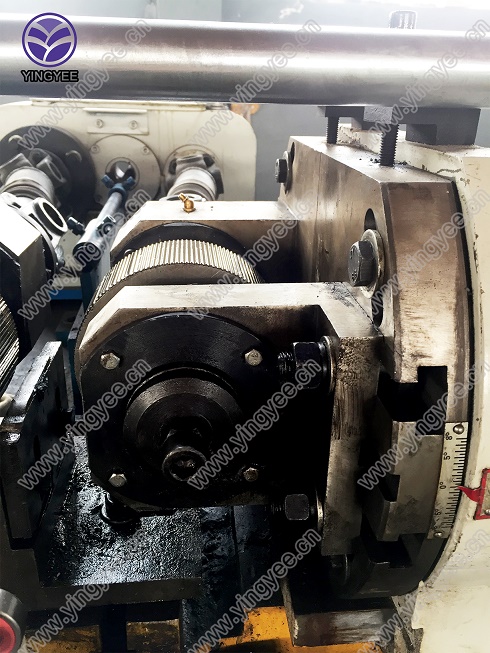

Light gauge steel framing involves the use of thin sheets of steel that are cold-formed into various shapes, allowing for the creation of strong yet lightweight structures. The light gauge steel framing machine automates the process of cutting, bending, and assembling these sheets into framing systems. This automation not only increases efficiency but also minimizes human error, ensuring consistent quality in production.

One of the primary advantages of using a light gauge steel framing machine is its speed. Traditional wood framing can be time-consuming, often requiring extensive labor and management. In contrast, these machines can produce framing components at a much faster rate, significantly reducing construction time. This speed not only translates to lower labor costs but also allows for quicker project completion, benefitting both contractors and clients.

Moreover, light gauge steel is inherently resistant to several environmental factors. Unlike wood, it is not susceptible to termites and does not warp or shrink due to moisture. This durability translates into fewer repair costs and a longer lifespan for structures built using steel framing. Additionally, steel's recyclability makes it a more sustainable choice, appealing to environmentally conscious builders and owners.

Another notable benefit of the light gauge steel framing machine is the precision it offers. These machines are capable of producing components with exact specifications, contributing to better overall fit and finish of the structures. This precision is critical in modern architecture, where design intricacies are increasingly demanding.

Furthermore, light gauge steel framing allows for greater design flexibility. Architects can explore innovative designs that were previously challenging with traditional materials. The lightweight properties of steel enable taller and more expansive structures while maintaining stability, pushing the limits of architectural creativity.

In conclusion, the light gauge steel framing machine represents a significant step forward in the construction industry. Its speed, precision, durability, and design flexibility provide substantial advantages over conventional framing methods. As the demand for efficient and sustainable building practices continues to grow, these machines are poised to become indispensable tools for builders and architects alike, shaping the future of construction. Embracing this technology is not just an option; it is essential for those looking to innovate and enhance their construction processes.