The Evolution and Significance of Drywall Forming Machines

In the construction and building industry, drywall has become a staple material due to its versatility, ease of installation, and efficiency. As demand for drywall continues to rise, so does the need for innovative machinery to enhance the manufacturing process. Among these innovations is the drywall forming machine, a vital equipment that transforms raw materials into finished drywall panels. This article explores the evolution, functionality, and significance of drywall forming machines in the modern construction landscape.

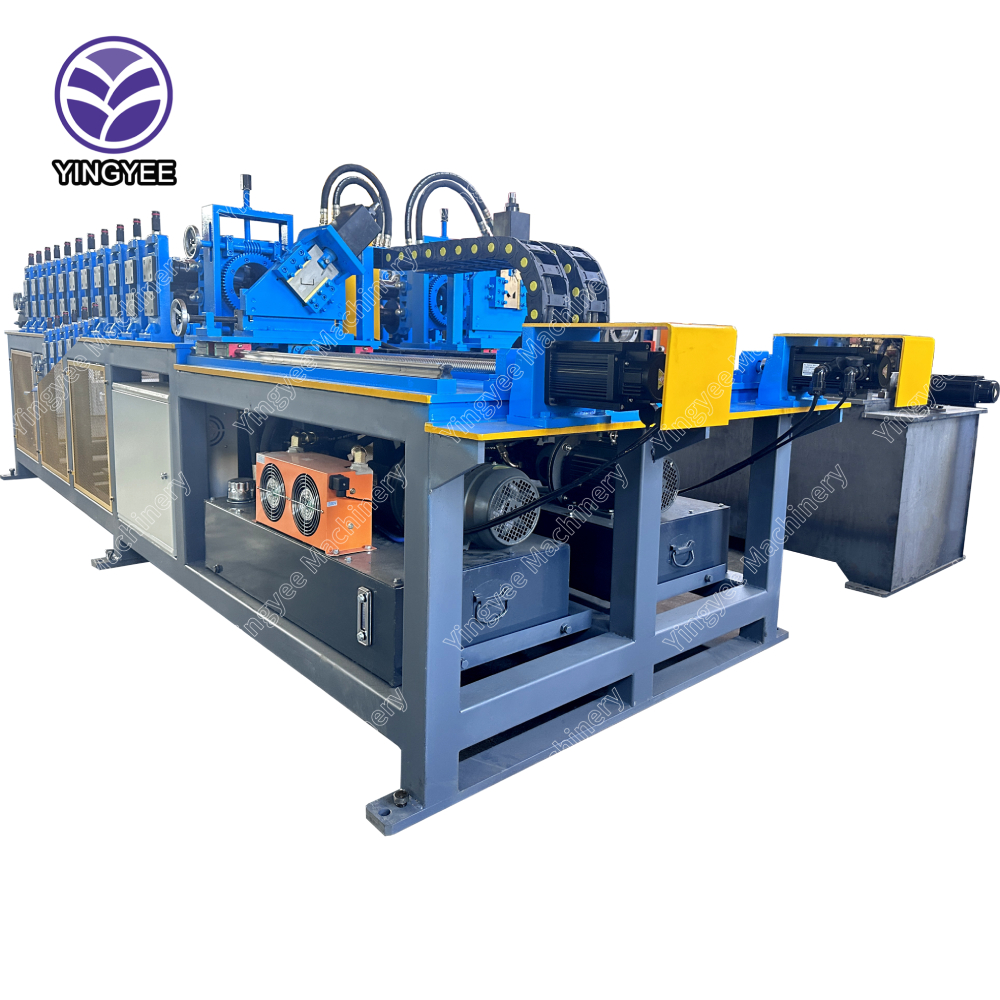

Understanding Drywall Forming Machines

A drywall forming machine is specifically designed to produce gypsum boards, commonly known as drywall. The machine integrates various processes, including mixing, forming, cutting, and drying, to create high-quality panels efficiently. These machines typically use gypsum, additives, water, and reinforcement materials to create the finished product.

The manufacturing process begins with the mixing of gypsum powder and water, along with any necessary additives for improved performance. Once the mixture reaches the desired consistency, it is poured onto a moving conveyor system, where it is spread evenly. As the board travels through the machine, it is shaped, cut into specific sizes, and dried to remove excess moisture. The end result is a strong, lightweight, and versatile drywall panel ready for various applications.

Technological Advancements

Over the years, drywall forming machines have undergone significant technological advancements. Traditional methods were often labor-intensive, requiring a substantial workforce and time. However, modern drywall forming machines are increasingly automated, integrating computer controls and robotics to streamline production. This automation not only boosts efficiency but also enhances precision in the manufacturing process.

Recent innovations have also focused on sustainability. Manufacturers are developing machines that can utilize recycled materials and eco-friendly additives in the production process. This shift is crucial in minimizing waste and reducing the environmental footprint of drywall manufacturing, aligning with the global push towards sustainable construction practices.

The Importance of Efficiency

In the fast-paced construction industry, time is a precious commodity. Drywall forming machines play a critical role in improving efficiency and reducing production time. By automating various stages of the manufacturing process, these machines allow manufacturers to produce larger quantities of drywall in a shorter period. This increased productivity helps meet the growing market demand for drywall, especially in large-scale construction projects.

Moreover, the precision offered by modern drywall forming machines minimizes product waste, ensuring that manufacturers can maximize their resources. This efficiency not only lowers operational costs but also contributes to a more sustainable manufacturing model.

Quality Control and Standards

Ensuring the quality of finished drywall products is paramount, as it directly impacts the safety and durability of buildings. Drywall forming machines are designed with quality control mechanisms that monitor every stage of the production process. From the initial mixing of materials to the final output, advanced sensors and software can detect inconsistencies and prompt immediate corrections.

Compliance with international quality standards is also a crucial aspect of drywall manufacturing. Drywall forming machines are engineered to produce products that meet specific performance criteria, ensuring that they are suitable for residential, commercial, and industrial applications. This adherence to quality not only safeguards the end-users but also enhances the reputation of manufacturers in a competitive market.

Conclusion

The drywall forming machine represents a critical advancement in the construction industry, significantly impacting the efficiency, quality, and sustainability of drywall production. As technology continues to evolve, we can expect further improvements in automation, material usage, and environmental considerations. This evolution will not only enhance productivity but also support the construction industry's shift towards more sustainable practices. As the market for drywall continues to grow, so too will the innovations surrounding the machines that produce it, ensuring that they remain a cornerstone of modern construction.