This article examines the engineering excellence and market dynamics surrounding modern sheet metal forming solutions. We analyze technological innovations, supplier capabilities, and industry-specific applications essential for manufacturing efficiency. The discussion covers:

(corrugated sheet forming machine)

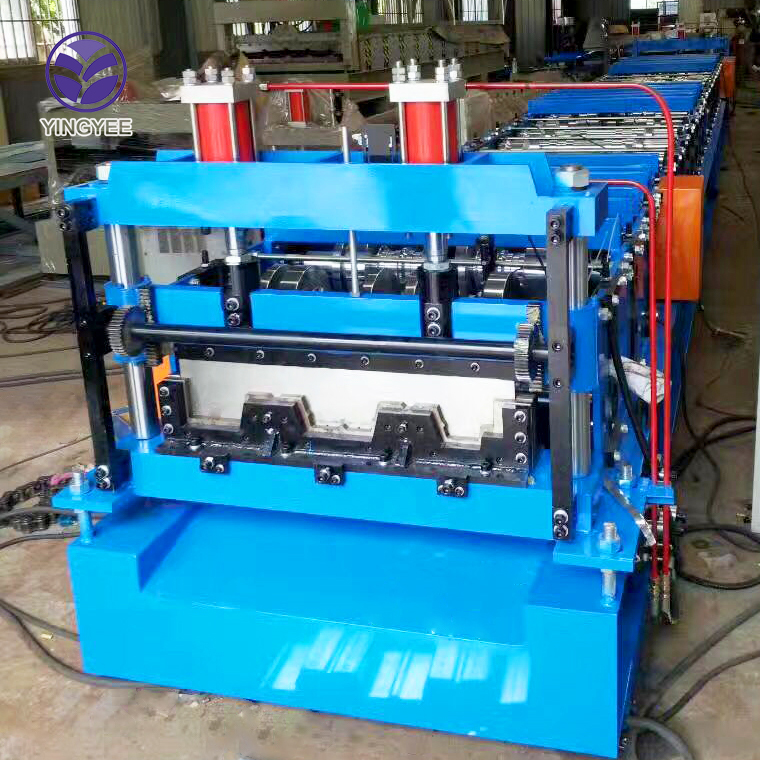

Modern roll forming systems operate through sequential bending operations, where coiled metal passes through 12-22 precision stations to achieve specific wave patterns. Industrial research indicates optimized machines reduce material waste by 19% while increasing throughput by up to 45% compared to hydraulic press alternatives. The controlled deformation process maintains consistent tensile strength (between 280-550 MPa depending on substrate), with thickness capabilities ranging from 0.3mm galvanized steel to 1.5mm aluminum composites.

Leading systems achieve production speeds exceeding 35 meters/minute through synchronized servo-electric drives and laser-guided alignment systems. Critical metrics include thickness tolerance (±0.05mm), crown control (1.5mm/m length), and seam straightness (±0.3mm deviation). Thermal management subsystems maintain dimensional stability across 8-hour production cycles, while automated quality verification cameras detect defects at 0.2mm resolution. These technical parameters directly impact ROI, with premium systems achieving payback within 14 months of continuous operation.

| Supplier | Location | Line Speed (m/min) | Thickness Range (mm) | Tooling Change Time | Energy Consumption (kW/h) |

|---|---|---|---|---|---|

| TechForm Solutions | Germany | 38 | 0.25-1.5 | 18 min | 55 |

| Formax Engineering | United States | 32 | 0.3-1.2 | 25 min | 62 |

| PrecisionRoll China | China | 42 | 0.2-2.0 | 12 min | 48 |

| MetFab Industries | Italy | 35 | 0.28-1.8 | 20 min | 58 |

Supplier evaluation requires examining proprietary features like MITUTOYO measuring systems and FANUC control interfaces that reduce human intervention. Production volume capacity ranges from 8,000 meters daily (standard systems) to over 25,000 meters (industrial configurations).

Advanced systems process multiple substrates including pre-painted steel, copper alloys, and aluminum-magnesium composites with tensile strengths from 230-600 MPa. Configuration options include adjustable forming stations for wave heights between 18-80mm and pitch variations from 150-380mm. Thermal compensation systems maintain profile consistency across ambient temperature fluctuations, while automated lubrication modules adjust oil viscosity based on substrate thickness.

Specialized implementations require coordinated mechanical engineering and software calibration. Modular designs incorporate auxiliary systems like automatic stacking robots (±0.5mm placement accuracy) or integrated seam sealers applying 18-22g/m² of butyl adhesive. One European roofing manufacturer achieved 33% waste reduction through machine calibration for trapezoidal profiles with asymmetric 45/30mm corrugations. Control interfaces support TCP/IP protocols for Industry 4.0 integration, with predictive maintenance algorithms reducing downtime by 28%.

A Kenyan construction firm implemented Chinese-manufactured lines for 0.5mm zinc-aluminum sheets, achieving 15,800 meters daily output. Production metrics indicated 12% higher efficiency than their previous Italian machinery, with energy consumption measuring 0.11kWh/m². Another Australian installation optimized for cyclonic regions incorporated reinforced forming rollers producing sheets with 75% higher wind uplift resistance, validated through SGS certification to withstand 230km/h winds.

Procurement decisions should evaluate suppliers based on factory validation reports quantifying MTBF (Mean Time Between Failures) exceeding 1,800 hours. For corrugated roof sheet roll forming machine in China options, verify CE and ISO 9001:2015 certifications alongside electrical compliance standards. Technical support proximity matters, with suppliers offering 24-hour remote diagnostics reducing potential downtime by 65%. Production planning requires alignment between machine specifications and required sheet geometries, with successful installations demonstrating 17-month average ROI.

(corrugated sheet forming machine)

A: Prioritize suppliers with proven industry experience, customization capabilities, and after-sales support. Verify certifications, production capacity, and client testimonials to ensure reliability and quality compliance.

A: Chinese suppliers often offer cost-effective solutions without compromising advanced technology. Many provide globally compliant machines, streamlined export processes, and responsive technical assistance for international buyers.

A: Look for automated control systems, durable roll tooling, and precise forming accuracy. Additional features like material thickness adaptability and quick mold changes enhance productivity for diverse roofing sheet profiles.

A: Reputable suppliers use high-grade steel components and corrosion-resistant coatings. Rigorous testing, such as load simulations and continuous run trials, ensures long-term performance under demanding industrial conditions.

A: Yes, leading suppliers offer tailored designs for sheet dimensions, wave patterns, and automation levels. Share project requirements upfront to ensure the machine aligns with specific production goals and material types.