Solar Strut Profile Roll Forming Line A Key Component in Solar Energy Infrastructure

As the world shifts towards sustainable energy solutions, solar power has emerged as a crucial player in the renewable energy industry. One of the fundamental elements supporting solar energy systems is the solar strut, which is essential for mounting solar panels securely and efficiently. To meet the growing demand for solar struts, efficient production processes are necessary, leading to the introduction of the solar strut profile roll forming line.

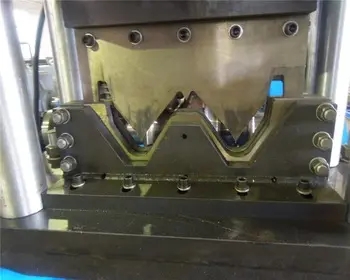

A solar strut profile roll forming line is a specialized piece of machinery designed to create various profiles of solar struts from metal sheets

. The process begins with feeding the metal strips into the roll forming system, where they are gradually shaped into the desired profile through a series of rollers. This continuous process allows for high-volume production with remarkable precision, making it ideal for manufacturers aiming to meet the surging requirements of solar installations.The roll forming line offers several advantages over traditional manufacturing methods. Firstly, it provides high efficiency, as the line can operate at speeds that are unmatched by other production techniques. This enables manufacturers to produce large quantities of struts in a shorter time frame, ultimately reducing production costs and lead times. Secondly, the roll forming process ensures a consistent cross-sectional shape, which is crucial for the structural integrity and performance of solar mounting systems.

Moreover, modern solar strut profile roll forming lines are equipped with advanced technologies such as computer numerical control (CNC) systems and automation. This integration allows for precise control over the dimensions and tolerances of the finished profiles, enhancing quality and reducing material waste. Additionally, these systems can easily adapt to produce various strut profiles, making them highly versatile.

Investment in a solar strut profile roll forming line not only supports the production of quality solar mounting solutions but also contributes to the overall sustainability of the environment. By enabling manufacturers to produce struts efficiently, these machines help to lower the costs associated with solar energy installation, promoting wider adoption of solar technology.

In conclusion, the solar strut profile roll forming line plays an integral role in the renewable energy sector. As the demand for solar energy continues to grow, innovations in manufacturing processes like roll forming will be essential for creating efficient, sustainable, and cost-effective solutions for solar panel installations, ultimately supporting the global transition to renewable energy sources.