The Benefits of Portable Roll-Forming Machines for Gutter Installation

In the world of construction and roofing, efficiency, precision, and quality are paramount. One revolutionary tool that has gained traction among contractors and builders is the portable roll-forming machine. This innovative equipment is particularly beneficial for gutter installation, transforming the way professionals approach this essential element of roofing systems. Let’s explore the numerous advantages of using a portable roll-forming machine for gutter installation and why it has become a game-changer in the industry.

1. On-Site Production

One of the most significant benefits of portable roll-forming machines is their ability to produce gutters on-site. This feature eliminates the need for transporting pre-fabricated gutters, which often requires careful handling to prevent damage. By producing gutters on-site, contractors can ensure that the fittings are tailored precisely to the specifications of each unique building. This customization reduces waste and enhances the overall fit and finish of the installation.

2. Reduced Material Waste

Traditional gutter installation methods often lead to excess material waste due to incorrect measurements or the need for modifications. Portable roll-forming machines minimize this issue by allowing for precise measurements and adjustments during the production process. As materials are fed directly into the machine, it can create gutters of various lengths as needed, significantly reducing waste and contributing to more environmentally-friendly practices.

3. Time Efficiency

Time is money in any construction project. The portable roll-forming machine streamlines gutter installation by significantly reducing the time spent on fabrication. With the capacity to produce gutters quickly and efficiently on-site, labor costs can also decrease. This speedy process allows contractors to take on more projects simultaneously, increasing overall productivity without sacrificing quality.

4. Versatility and Adaptability

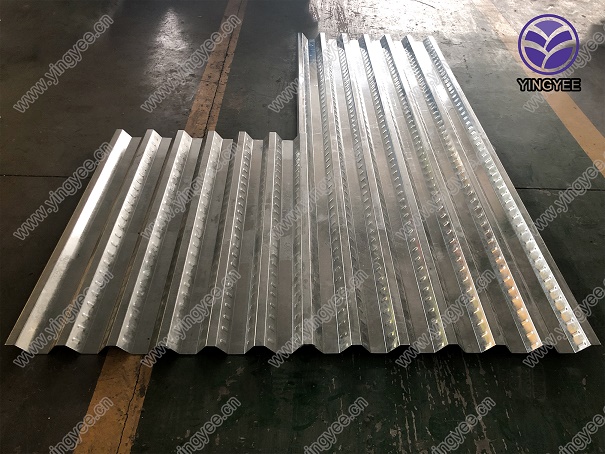

Portable roll-forming machines come equipped to handle various materials and designs, making them suitable for diverse applications beyond just gutter installation. They can easily switch between different profiles and styles, accommodating changes in design requirements as needed. Whether dealing with aluminum, steel, or copper, these machines provide the flexibility to cater to different project specifications, enhancing their utility for contractors.

5. Improved Quality Control

With portable roll-forming machines, contractors can maintain strict quality control over the gutter production process. As everything is done on-site, it allows teams to monitor every step of the creation, ensuring that the gutters meet high standards of durability and finish. Additionally, the precision of the roll-forming process results in fewer imperfections, leading to an overall higher quality product that performs better over time.

6. Cost-Effectiveness

Investing in a portable roll-forming machine can lead to significant cost savings in the long run. While the initial purchase may seem substantial, the reduction in labor costs, decreased material waste, and enhanced efficiency can yield high returns on investment. Furthermore, expedited project timelines allow contractors to take on more projects, indirectly boosting profitability.

7. Ease of Transportation

The portability of these machines is another noteworthy advantage. Measuring just a few feet in length, they can easily be transported to various job sites without the need for specialized vehicles. This ease of transport enables contractors to respond quickly to client needs and tackle urgent projects without delay.

8. Enhanced Safety

Safety is a critical concern on any construction site. By using portable roll-forming machines, the risks associated with handling large, pre-fabricated gutters are minimized. The efficiency of on-site production reduces the need for heavy lifting and extended storage periods, thereby enhancing overall safety for workers.

Conclusion

The use of portable roll-forming machines for gutter installation presents a multitude of benefits that modern contractors can leverage to improve their workflow and project outcomes. From on-site production and material waste reduction to enhanced quality control and cost savings, these machines are making a significant impact in the construction industry. As technology continues to evolve, embracing tools like portable roll-forming machines will be essential for staying competitive and meeting the demands of today’s construction projects. Investing in this innovative solution not only enhances efficiency but ultimately leads to a superior product that satisfies clients and solidifies a contractor’s reputation in the market.